Last month we received a name: Taycan. As evocative as Mission E was for a concept, it was clear that it wasn’t going to cut it in Porsche’s current naming scheme. The name is apparently roughly translated from Uzbek and is meant to invoke a “lively young horse.” Upon looking at the recently-released specifications, this will be a very lively young horse indeed. Each number seems to be preceded by a “greater-than” symbol, save for the acceleration figures where the carrot is reversed.

In keeping with the brand’s energy objectives, as well as tightening emissions regulations the world over, the Taycan will help to improve Porsche’s emissions when calculated in across the brand’s model range. With electric vehicle sales on the rise, it is key for Porsche to stay on the bleeding edge. Worldwide electric vehicle sales are sharply on the rise, with a 55% increase in the first portion of 2018 when compared to the same period in 2017. More than 1.2 million electric cars are on the road in China, and 750k in the US in 2018. New registrations are expected to exceed 25 million by 2025.

We already know that Porsche is planning to double its investment in battery-powered hybrid and full-EV cars over the next several years. Total investment by 2022 will exceed 6 billion Euros. Sales of electric vehicles are expected to hit 25% of the company’s output by 2025. What we didn’t know until now were the down and dirty specifications of the first all-electric model. The figures show that the Taycan will be pretty special. Here are the headlines:

- Output: >600 Horsepower (440kW)

- System Voltage: 800v

- Range: >500km

- 0-60 Time: <3.5 Seconds

- Number Of Prototypes: >100

Porsche Taycan Drive Unit

Porsche wishes to stay ahead of all other German manufacturers in electromobility. By 2025 they strive for every second Porsche to have an electric drive unit, either as part of a hybrid powertrain, or as the vehicle’s sole motive power. But for this to work, these electric vehicles must remain emphatically Porsches. For that, the drive unit must be given careful consideration.

Porsche engineers have embraced the brand’s principle of intelligent performance. “We opted for a permanently excited synchronous motor(PSM) in the Taycan,” reports Heiko Mayer, drive unit project leader. “They combine a high energy density with strong sustained performance and maximum efficiency.” These units are similar to those used in the Le Mans-winning 919 Hybrid. These units generate a permanent rotary motion that can be applied at any time without needing to be started.

PSM electric motors offer extremely high sustained performance and maximum efficiency. They Taycan will be equipped with one for each axle, and generate over 600 horsepower combined. This powerplant can accelerate the Taycan from 0-100kmh (0-62 mph) in well under 3.5 seconds, and 200 kmh (124 mph) in under 12 seconds. Porsche promises that the new electric drive technology is track-ready as well.

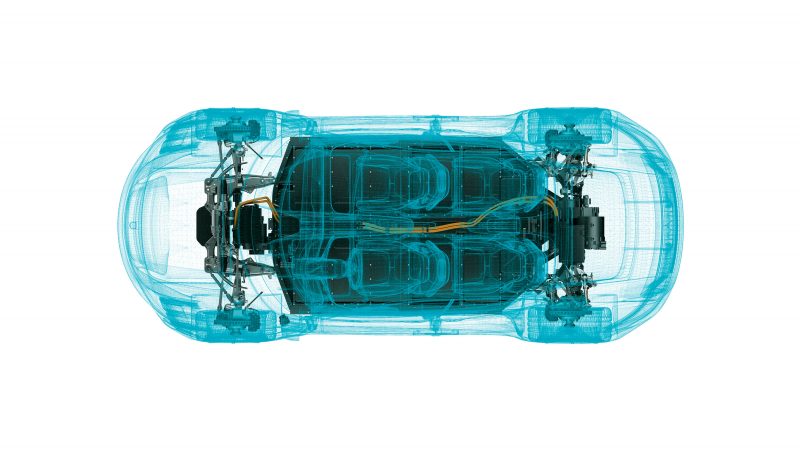

The PSM motors are also very compact thanks to several advancements by Porsche. The solenoid coils are shaped from rectangular wires rather than round, enabling more efficient packaging for a given volume. The Taycan’s power accessories are also tuned for efficiency. The inverters, which switch battery output to alternating current, operate on a steplessly variable pulse frequency helping to keep the motor at its optimal operating point. The cooling system is similarly linked, diverting cooling water around the car on-demand.

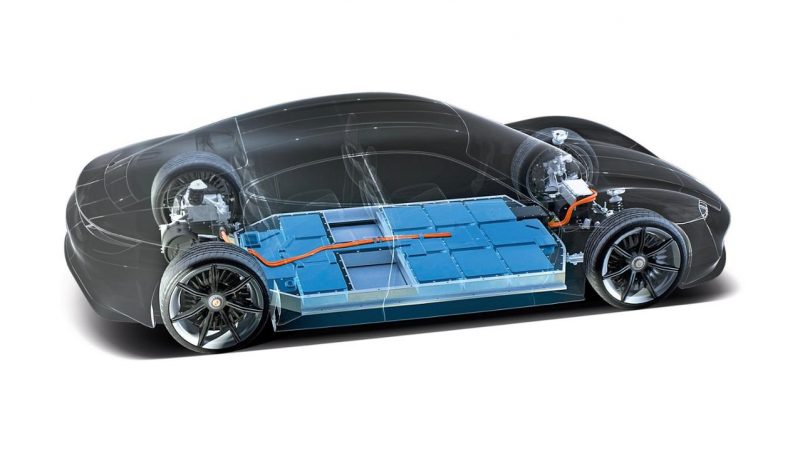

Porsche Taycan Battery Pack

Development of the battery pack was driven by managing weight, temperature, and considering the sustainability of raw materials. Ranges of over 500 kilometers are already possible, though typically through the use of a very large and heavy battery pack. Porsche demands that their system offers speed and lightness, as well as range and sustainability.

The Porsche system calls for emphasis on fast charging rather than out-and-out maximum range. The 400 cell pack sees the individual cells connected both in series and in parallel. Each cell has a current of roughly 4 volts, and are controlled by a battery management system for the 800 volt system. “It was a major challenge to achieve such enormous battery capacity both for charging and discharging over the entire temperature range,” says Nora Lobenstein, head of all energy storage systems at Porsche. The solutions include an intelligent charging protocol and an efficient heat-exchanger system. The latter helps to achieve operating temperature swiftly, and maintain it under heavy loads. The objective of the fast-charging system is a 400km range in about 15 minutes.

Porsche developers are also studying how Taycan’s batteries can be reused in the future. Porsche vehicles typically have extremely long life cycles, and Porsche wants to plan for this future. As the car lives on, so too should the batteries.

Charging

The current global infrastructure does not support recharging electric cars. That is, it does not support it in the same way as refuelling a conventionally powered car. To help overcome these challenges, Porsche is getting to work on the ground floor, both making the Taycan work with the current infrastructure, and helping establish networks for the future.

The company is pursuing three avenues. The first is charging at home using a charging station or inductive base plate in the floor. The second, charging in cities, is possible through existing infrastrucutre. The third, is charging along the main ateries in Europe. Through Ionity, a joint venture with BMW Group, Daimler AG, the Ford Motor Company, and the Volkswagen Group with Audi, Porsche is helping to lay the groundwork for a network of fast-charging stations in Europe. The project’s goal is for charging stations to emerge every 100-150km along the European road network. Thus, by 2020 electric vehicle users will have access to brand-independent High-Power Charging (HPC) points. The system will give capacity of up to 350kW per charging points, dramatically speeding up the charging process.

Porsche’s own system will use intermediary buffer batteries, which help maintain capacity even when the local charging grid is weak. These Porsche charging points will offer 400 kilometers of range in about 15 minutes. Operation of the stations is meant to be about as intuitive and secure as an ATM. Porsche’s system will be compatible with virtually any electric vehicle.

Testing

Porsche reports that more than 100 Taycan prototypes have been built, with many being used for testing in extreme weather. Like the Macan, Porsche has used areas of South Africa for hot weather testing. Daily temperatures are around 40 degrees celsius, and are designed to challenge the machine to the limit. More than 40,000 kilometers were covered on a single trip for hot weather testing, and millions will be covered in all conditions by the time the car goes on sale in late 2019.

The Taycan is being extensively tested within Porsche as well. The prototype construction department at Zuffenhausen is the birthplace of every new model; Taycan included. Each of the strides needed to make the car had to happen here before they went into production, or even on to a test vehicle.

But most importantly the first all-electric Porsche must remain a Porsche.