My 1976 Porsche 912E is a few years older than I am, and as such it deserves a little rest and relaxation lately. It’s lived a long hard life with a lot of abuse. My goal over the next few posts on the car are to get it back into mechanically tip top condition. The body is perhaps in need of some serious help, but for now that’s going to have to remain untouched. This car has earned its patina, but it doesn’t deserve to have all of this long-term mechanical neglect. It was pulled out of a barn in California about six years ago, sat in a shop untouched for another two years, and I’ve been slowly stringing it along since I got it four years ago. It’s lived too long like this, so we’ll jump into a few refreshing restorative projects.

First on the list is to get the brakes back up to snuff. I did pads and rotors when I got the car, but it’s never really been properly good at stopping since I got the thing. It needs a deeper dive into the system to get rid of a soft pedal and sticky caliper issue. I’ve done what I can do with my shade tree mechanic skills, so I figured it was time to call in the professionals. A quick discussion with my friend Eric Shea at PMB Performance netted me a slot in their lineup of caliper restorations.

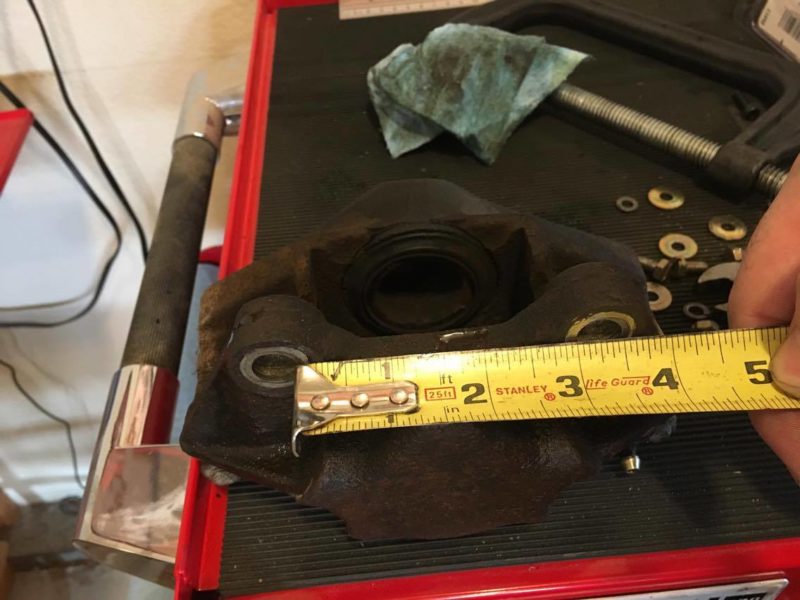

The first step was to figure out exactly which calipers I have, because the 912E was built with both “A” type calipers and “M” type calipers. Measuring the gap between mounting ears on the caliper itself will tell you the difference, as they two have different mounts. The ATE A caliper is the wider of the two, as pictured below. If your measurement is less than shown in the below photo, then you have M calipers. This is important, because it will help determine the needed caliper rebuild kit and the correct fitment brake pads. I got a set of Hawk HPS pads for a little more spirited braking performance.

On a nice long Saturday I put the car up on jack stands and removed everything from the car. To keep everything sorted, I bagged and labeled the calipers, pads, and hardware separately. This is shown in the above photo. I then boxed everything up and shipped it on down to PMB for a full treatment.

As you can see from the photos, my car’s calipers have seen better days. They’re dirty, grimy, and have lots of baked on brake dust. It’s time for them to shed their skin.

PMB first strips the calipers down to their component parts before stripping the bare cores down to a clean metal finish.

Then the calipers are re-plated back to their original cadmium coating, while the brake pistons are polished to an anti-friction sheen.

All of the hardware is also properly cleaned and coated. The pistons are installed and fitted with seals and dust boots.

The caliper pistons are then pushed down into their bores.

And the dust boots are c-clipped to the surface of the caliper.

Each caliper is then re-assembled with new caliper half seals to keep them from leaking.

And the hardware is torqued down and marked to as-new spec.

Don’t they look so pretty? Almost too good to install on this scruffy lookin’ old 912E. Having seen the finished product with my own eyes, I can definitively say that this is well worth the $325 per axle price that PMB charges for the service. If I didn’t know any better, I’d say that they had a set of new old stock ATE calipers sitting on the shelf and shipped me those. These look absolutely back to factory, and their customer service is incredible. Well worth $650 for your Porsche and a bit of peace of mind.

The calipers returned to me a couple of weeks after I sent them off. PMB surprised me with a brand new set of pre-bent caliper hard lines, and fresh bleeder screws, which were desperately needed all around. The original pad retaining posts and butterfly spring keepers were all cleaned up and returned, as there are many of these little hardware pieces which are just impossible to find new. Make sure you don’t misplace yours!

It took me about two months between removal and re-installation, which explains the rust on the surface of the rotors.

With a set of fresh ECS Tuning braided stainless soft brake lines and freshly bent hard lines, mixed with the now bone-dry calipers, the system needed quite a lot of brake fluid to re-fill all of the lines. Because the 912E has a brake overflow line I couldn’t use my brake bleeder with the system, so I had to use the old press-and-hold pedal method. It took a few tries to get all of the air out of the lines, but it was still pretty straightforward, and super easy to do thanks to those new bleeder screws.

And now it’s back on four wheels with a fresh ability to stop better than since I’ve had the thing.

Now the tired engine needs a proper rebuild. Let’s go!