Porsche’s inaugural attack on the FIA’s World Endurance Championship in 2014 came with a host of challengers, most notably in the form of Audi and Toyota, not to mention the challenges of pace and reliability inherent in any endurance racing championship. Throughout the season, however, there was one challenge faced by the team that had nothing to do with the performance of the cars, and the drivers never once had to even think about; shipping logistics.

A true World Championship, the WEC races for a total of 66 hours at 8 different tracks on 4 continents. The first half of the schedule takes the team to locales that are a bit closer to home in the UK, Belgium, and France. The second half, though, sees the team booking flights to far flung Austin, Fuji, Shanghai, Bahrain, and Sao Paolo. The team’s travel itinerary for the full 8-race season adds up to a total of more than 53,200 miles. It takes a whole lot of stuff to make the magic of racing near 1000 horsepower hybrid prototypes happen, and Porsche estimates their team kit to weigh around 35 tons.

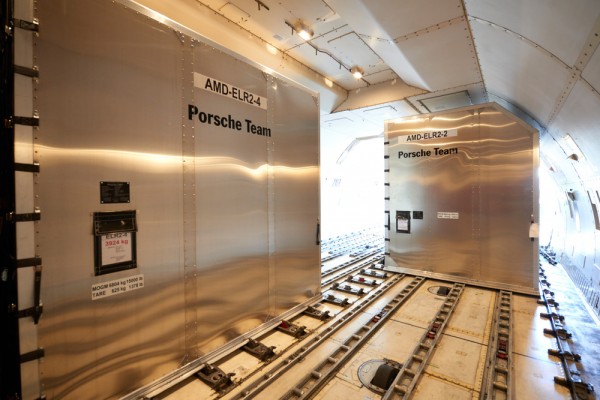

Porsche has stated that their shipping undertaking is equivalent to a game of Tetris, arranging their items as tightly as they can. Air cargo is about as complex as it gets. Porsche makes a habit of using the aircraft’s hold, not forgetting to include the curved sections. Porsche is limited to a total of 12 containers of no more than 300 kilos each, otherwise they incur further expense from DHL’s freight shipping. The containers are designed specifically to fit inside a 747 snugly, saving the need for a restraining net, which in itself allows the containers to be about a centimeter and a half taller. Each flight, Porsche has two very large containers that have a spare chassis in one, and over 100 wheel rims in the other.

Each of the 12 containers holds literally hundreds of items, and all of them have to be meticulously counted and itemized. The loading of each container started well before the season even started, as Porsche had to take each purchase into consideration, trying to make the best use of space. Every time they pack the containers, they have to keep in mind what will be needed first once they arrive at the track, saving those items to be packed last. The key to the whole operation is perfect organization. Each unit is given a unique shipping license plate, and every single part packed inside is labeled with a scanable QR code. Each of 120 team radios is listed by serial number. This not only helps expedite the unpacking process, but it also helps expedite the process of going through customs offices. Each container receives an X-ray scan on entry, and of course, the customs offices may want to unpack each container, so Porsche has to be sure it is simple and easy to repack.

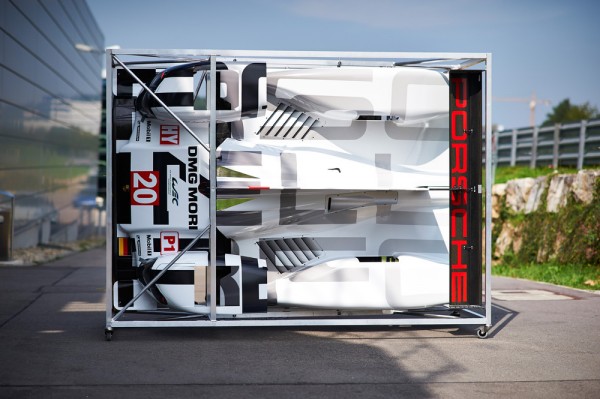

In addition to the 12 containers, a pair of complete 919 Hybrid race cars travel to the track strapped down onto a double decker car rack. Each car has its fluids drained out, and its fragile body parts have been removed and stowed somewhere safe. Each car has a set of worn race tires fitted to keep the suspension components protected during shipment.

Hazmat products ship separately, because they have to. Adhesive products, resins, aerosol cans, and the lithium-ion batteries for the hybrid systems all ship together. The batteries, interestingly, require special permission from the federal aviation administrations of various countries in order to fly. All of the hazardous materials are required to stay in a secured room for 48 hours before and after each flight without being moved. Luckily, Porsche doesn’t have to worry about shipping certain things, because their partners ship all of their fuel (Shell), oil and lubricants (Mobil), and tires (Michelin).

To save on some shipping costs, Porsche will send some items by sea freight. This, of course, means that the parts ship much slower. Because of the long distances covered, and the lengthy shipping times, Porsche makes three full sets of sea freighted parts. The sea shipments consist mainly of parts that are inexpensive to purchase, yet heavy and expensive to fly. One example they give is a set of 20 tensator barriers used to keep the public out of their garages. It is apparently cheaper to buy 60 of them and ship them to three different places than it is to buy one set and fly them around the world. Efficiency, efficiency, efficiency.

When Porsche’s containers are packed in a DHL 747 cargo plane, they ride peacefully alongside their WEC competition, just waiting inside the belly of the plane for the moment when they can be unleashed on track.

Other Porsche Blog Posts You Will Enjoy

What Is A Climatic Wind Tunnel And Why Did Porsche Just Purchase One

The Last Turn

7 Airports Where A Porsche Might Meet You At The Gate When Flying Delta

Porsche’s Shanghai Six Hour Success