Besides the obvious of winning races and setting fast laps one of the major things that differentiates one Porsche from another on the track is its livery; the colors and distinctive markings a team chooses to brand themselves with. When it comes to the more complex liveries, like that of the Team Falken Porsche, I always assumed they were wrapped front to back. Not only did it seem practical and less expensive, it just seemed the way to go in the event of accident or contact. However, according to a post we read recently on the team Falken Tire’s blog we were completely wrong. They paint the car and repaint any damaged parts as needed. Read on and you’ll see just how much is involved in getting their Porsche prepared.

The 2012 Team Falken Tire Porsche at Lime Rock

Since Falken Tire started racing in the American Le Mans Series in 2008, the team vehicles bore the corporation’s unique livery. The teal front end leads into a bold, blue rear, with Falken’s signature scallops on the doors and roof of the car. Here is a look at the intricate process of creating the look of the No. 17 Falken Tire Porsche.

Note the shipping tag hanging from the tow hook

A new car arrives to the team in white, without team liveries or sponsor logos. If you look closely, here, the 2012 Porsche still has the shipping slip.

In order to create the Team Falken livery, every part of the Porsche receiving paint first gets sanded down. Once the factory gloss is gone, the new layer of paint will be smooth and stick to the body of the 911. Any area not getting paint is masked. Since different parts of the Porsche get painted at different times, not all of the covering is applied at once. From start to finish, taping up the 911 takes a minimum of four hours.

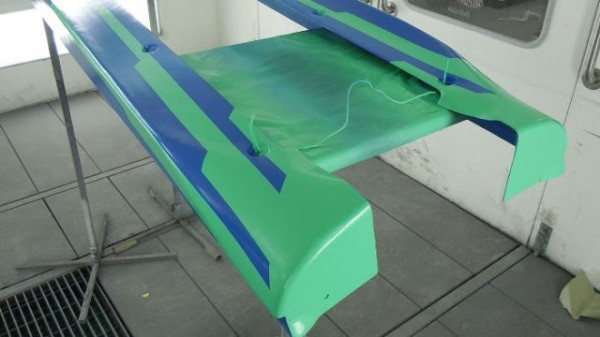

Body parts of the 911 are removed, and the teal layer is the first color applied to the Porsche.

Once the teal dries, portions of the 911 are covered again to protect from the next phase of blue paint.

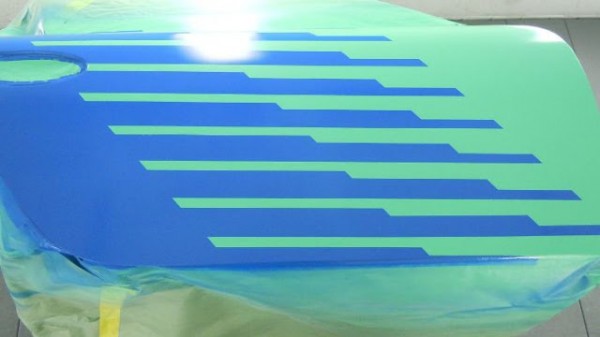

To create the Falken Tire signature scallops on the door panels and the roof of the Porsche, a vinyl mask is used when spraying on the blue paint. To keep the branding of the signature look consistent, the Falken Tire team provides the painter with specific guidelines of the car’s design. When applying the vinyl mask to the 911, the doors are put back on the Porsche to ensure the design stays even across the roof and doors. After the mask is applied, the pieces are then taken back off the car to be painted. Due to the Porsche’s low ride height (50mm), the rocker panels below the doors suffer usual wear and tear, and need to be repainted often.

Once the colors are on the 911, the painter applies a clear coat to encapsulate the color and add shine. After an hour of drying, the bodywork is complete.

If a piece of body work suffers contact, it gets repaired, sanded down, and painted again with the proper colorand clear coat. Here you can see some pieces of the Porsche after sanding. They are prepped and waiting for their colors.

Once the Porsche is fully dry, all of the team and sponsor logos are placed on the car according to the specifications of Falken Tire and the International Motorsports Association.

Each crew member’s helmet is painted by the same process. With the helmets, it’s imperative that the vinyl mask is applied correctly and that the angles for the Falken scallops are kept the same. All of the helmets are painted at the same time, following the same process.

Other Porsche Blog Posts You Will Enjoy

Should Historic Liveries be an Option on all Porsche sports cars?

Porsche 918 Gets Historic Martini Racing Livery as Option

Lego Porsche Racing Liveries

[This post originally appeared on the Team Falken Tire blog. It was edited and reprinted with their permission]